The Structure of Heavy Truck AC Evaporator

The structure of a heavy truck AC evaporator consists of several key components that work together to facilitate the cooling process. Here is a typical structure of a heavy truck AC evaporator:

Housing: The evaporator is housed within a metal or plastic enclosure, which is usually located inside the truck's cabin. The housing provides protection and support for the internal components.

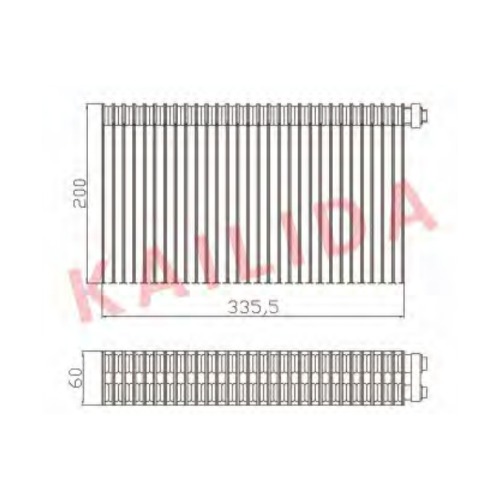

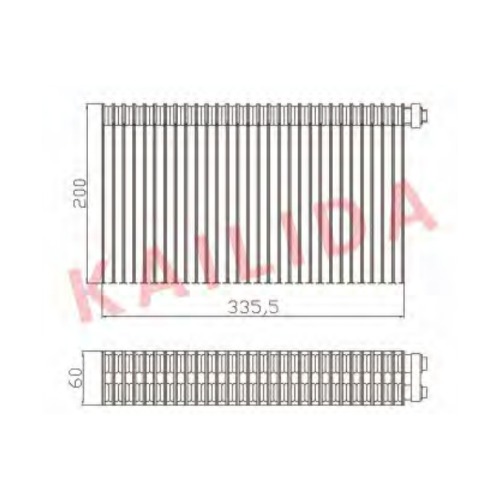

Finned Tubes: The evaporator core contains a series of finned tubes that are responsible for transferring heat from the air to the refrigerant. These tubes are typically made of aluminum or copper and are arranged in a serpentine pattern to maximize the surface area.

Fins: Thin metal fins are attached to the outside of the tubes to further increase the surface area available for heat transfer. The fins help in dissipating heat and improving the efficiency of the evaporator.

Refrigerant Flow: The evaporator receives cold, low-pressure refrigerant from the expansion valve or orifice tube. As the refrigerant flows through the evaporator tubes, it evaporates, absorbing heat from the air passing over the fins and tubes.

Air Distribution: The evaporator has an inlet and outlet for the airflow. The blower fan inside the AC system draws warm air from the cabin through the evaporator, where it is cooled, and then blows the cooled air back into the cabin.

Drain Pan: The evaporator typically includes a drain pan at the bottom to collect any condensation that forms as a result of the cooling process. The collected condensation is drained out of the evaporator through a drain hose.

Expansion Valve/Orifice Tube: The expansion valve or orifice tube is located before the evaporator and controls the flow of refrigerant into the evaporator coil. It regulates the pressure and temperature of the refrigerant entering the evaporator.

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体